一、Product Description

|

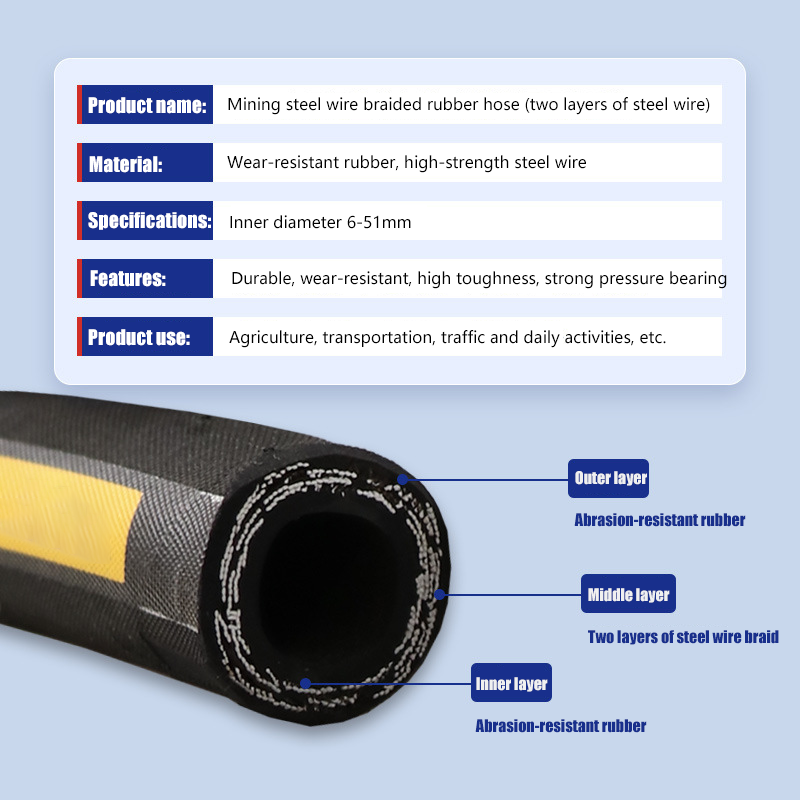

1.Hydarulic hose Structure:

|

|

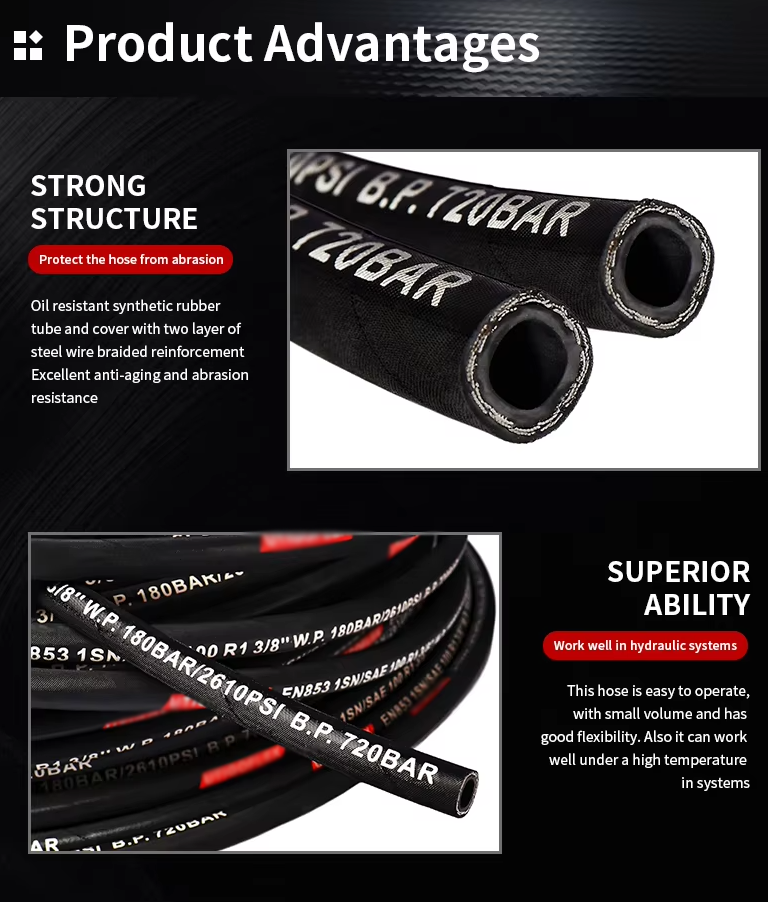

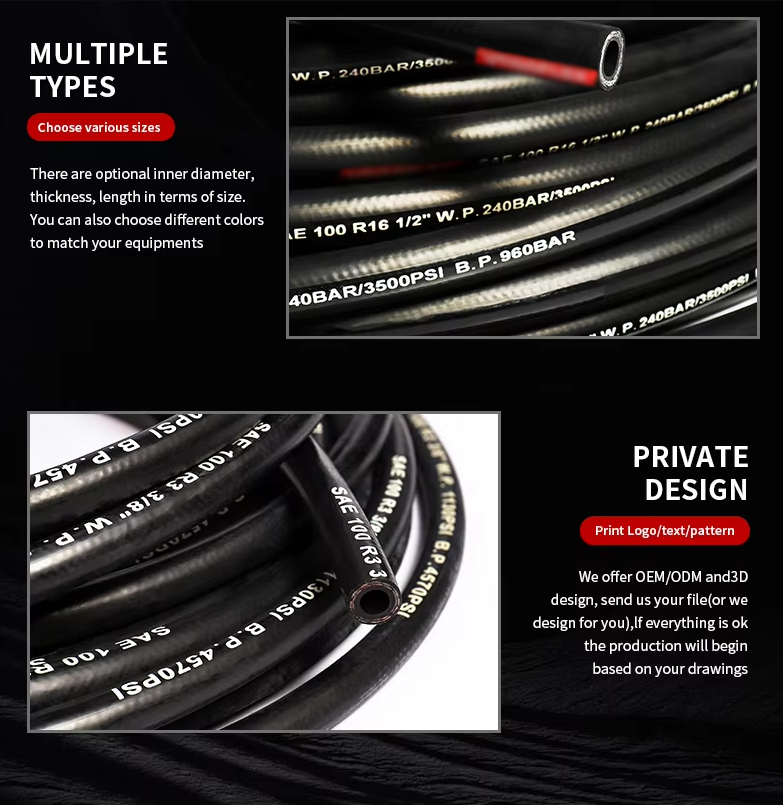

2.Product features

|

Please reference the hose standard :

|

Wire braided Rubber hose

|

1.SAE 100R1AT/EN853 1SN/EN 857 1SC

|

|

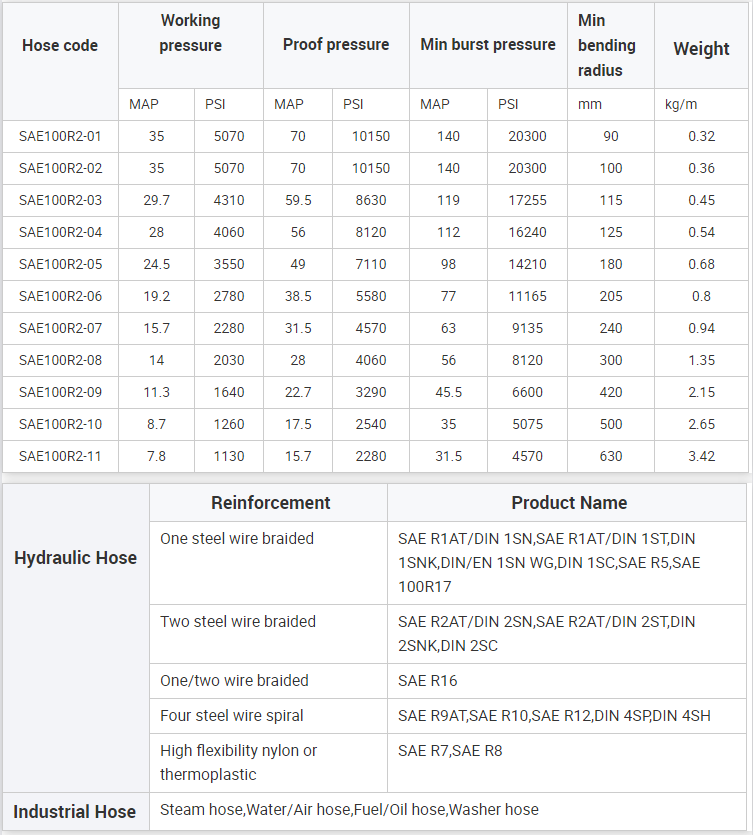

2.SAE 100R2AT/EN853 2SN/EN 857 2SC

|

|

|

3.SAE 100R16

|

|

|

4.SAE 100R17

|

|

|

Wire spiralled Rubber hose

|

1.SAE 100R9/ EN856 4SP

|

|

2.SAE 100R10/ EN856 4SH

|

|

|

3.SAE 100 R12

|

|

|

4.SAE 100 R13

|

|

|

5.SAE 100 R15

|

|

|

Fibre braided Rubber hose

|

1.SAE 100R7/EN855 R7

|

|

2.SAE 100R8/EN855 R8

|

|

|

3.SAE 100 R3

|

|

|

4.SAE 100 R6

|

|

Choose the suitable hydraulic hose

|

|

Selection of the proper Hydraulic hose for the application is essential to the proper operation and safe use of the hose and related equipment. In adequate to selection of the hose for your application can result in hose leakage , bursting or other failure,which can cause serious bodily injury or property damage from spraying fluids or flying projectiles. Therefore when choosing hydraulic hose , we should consider below factors:

|

|

1. Hose Size 2. Hose Length 3. Hose Fittings 4. Fluid Conveyed 5. Bends 6. Temperature 7. Hose pressure 8. Static Head Pressure 9. Installation Design

|

|

We also have other bigger size hydraulic hose. If you are interested, you can contact with us.

We can product according to your demands. |

|

3.Product Application:

|

三、Packing & Delivery

三、Company Profile

Since its establishment in 2012, Jinghuan Rubber & Plastic has been deeply engaged in the research and development and manufacturing of rubber and plastic products for thirteen years. Relying on the modern enterprise management system and the layout of the entire industrial chain, it has built an intelligent manufacturing industry ecosystem integrating research and development, production, testing and sales. The company’s core product lines cover four categories: hydraulic crimping equipment, large-diameter rubber hoses, smooth low-pressure oil-resistant hoses and PVC hoses, which are widely used in engineering machinery, petrochemicals, municipal engineering and other fields. Its independently developed high-precision crimping equipment and special rubber composite material technology have broken through many technical barriers in the industry.