Using high-quality natural rubber or synthetic rubber as the inner rubber layer, it has good oil

resistance, corrosion resistance and sealing, and can ensure the safe delivery of fluids.

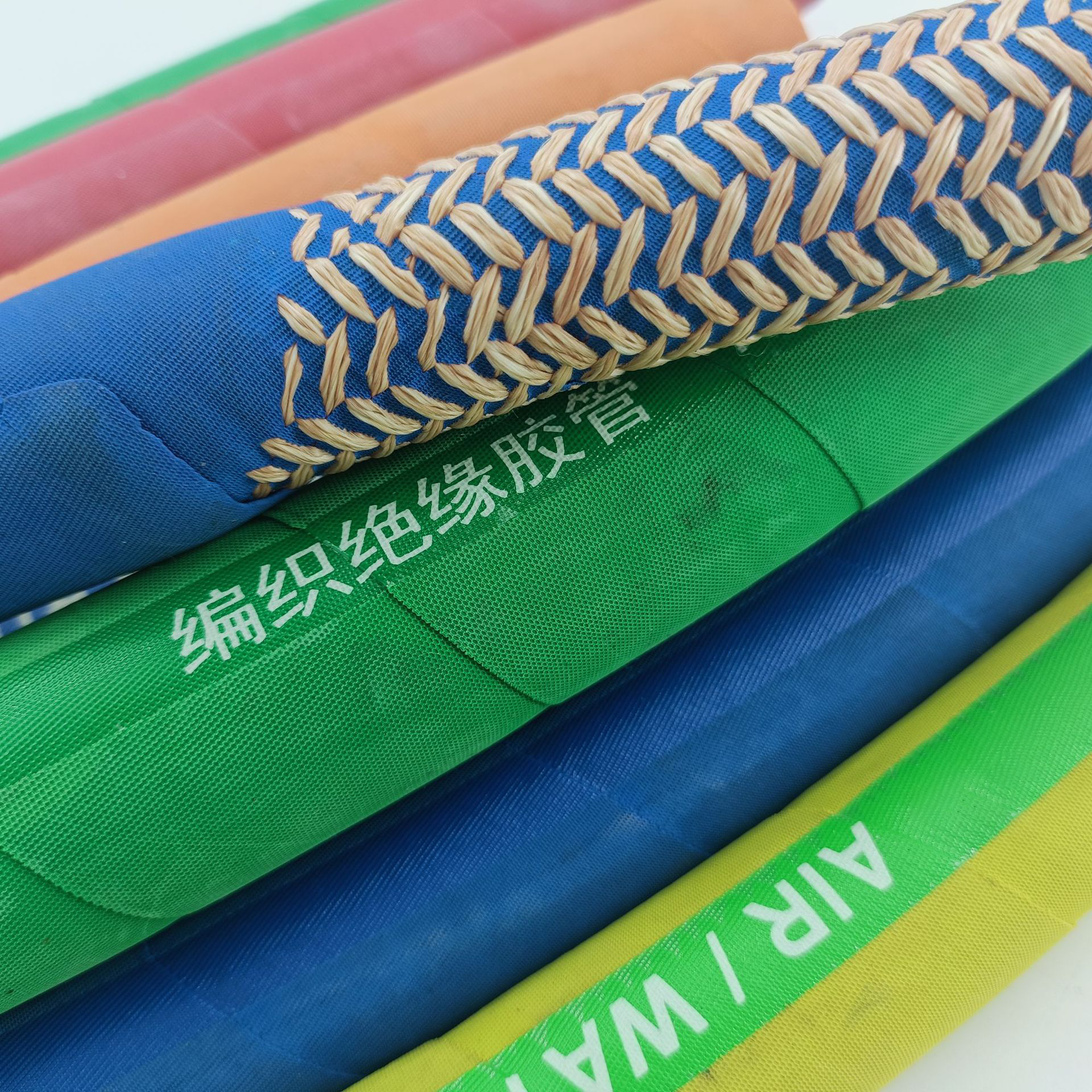

The outer layer is woven with high-strength fiber wire or metal wire, which enhances the pressure resistance and tensile resistance of the hose, enabling it to withstand a certain amount of pressure and tension without breaking.

② Exquisite craftsmanship:

Adopting advanced weaving technology, the wires are woven tightly and evenly to ensure the structural strength and stability of the hose. Each wire is strictly screened and inspected to ensure the quality and reliability of the product.

Strict production process control ensures the dimensional accuracy and appearance quality of the hose. Each hose is strictly inspected and tested to ensure the performance and quality of the product.

③ Good flexibility :

The hose has good flexibility and can be easily bent and twisted to adapt to various complex installation environments. Whether in a narrow space or in a curved pipe, it can be easily installed and used.

Good flexibility also makes the hose not easy to break and damage during use, extending the service life of the product.

④Multiple specifications available:

We provide low-pressure wire braided hoses in multiple specifications, including different parameters such as inner diameter, outer diameter, length, etc., to meet your different application needs. Whether you need a small-diameter hose for fine fluid delivery or a large-diameter hose for large-volume fluid delivery, we can provide you with the right product.

It can be customized according to the special needs of customers, such as special colors, special joints, etc., to meet your personalized needs.

⑤Safe and reliable:

After strict pressure testing and quality inspection, ensure that the pressure resistance and sealing of the hose meet the relevant standards and requirements. During use, it can ensure the safe delivery of fluids without leakage and other safety problems. Good wear resistance and anti-aging properties make the hose not easy to damage

and age during long-term use, ensuring the reliability and stability of the product.

①Industrial field:

Used in various fluid delivery systems in factories, such as oil, water, gas, etc. It can be applied to machinery manufacturing, automobile manufacturing, chemical industry and other industries to provide reliable fluid delivery guarantee for industrial production. Connecting hoses suitable for pneumatic tools, hydraulic equipment, etc. in factories can withstand certain pressure and vibration to ensure the normal operation of equipment.

②Agricultural field:

Used in agricultural irrigation systems, it can deliver water to every corner of the farmland and provide sufficient water for the growth of crops. It has good corrosion resistance and wear resistance and can adapt to the harsh environment of farmland. It can be used in the hydraulic system and fuel delivery system of agricultural machinery to provide guarantee for the normal operation of agricultural machinery.

③Home field:

It is suitable for home tap water pipe connection, garden watering and other scenes, which is convenient and practical. It has good flexibility and appearance quality and can meet the needs of home users. It can be used in the home gas delivery system, but it is necessary to pay attention to the selection of hoses that meet the gas delivery standards.

Type of fabric hose:

1. Water delivery hose: suitable for general water delivery, used in environments of-20℃ -45℃

2. Air hose: suitable for conveying compressed air and inert gas, used in an environ-ment of -20 °C -45 °C.

3. Oil resistant hose: suitable for transporting conventional petroleum and used inenvironments of -20 ‘C -45 °C.

4. Steam hose: suitable for conveying hot water or saturated steam below 170 °Cused in an environment of -20 °C -45 °C.

5. Heat resistant rubber hose: suitable for conveying water below 100°C.

6. Acid and alkali resistant hose: Transport dilute acid and alkali solutions of farmersbelow 40%, and use them in an environment of -20 °C -45 °C.

7. Sandblasting hose: suitable for wind pressure sandblasting rust removal and poli-shing on metal surfaces.

8. Suction and drainage, oil hose: Working pressure is 1.0-1.5MP (four times safety factor)

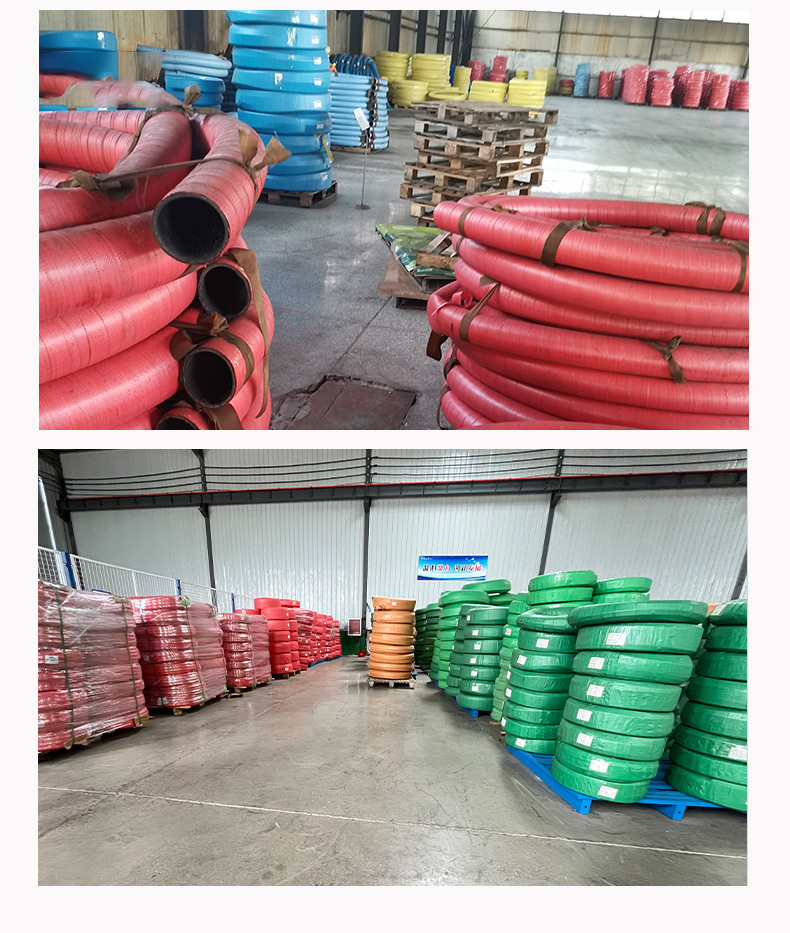

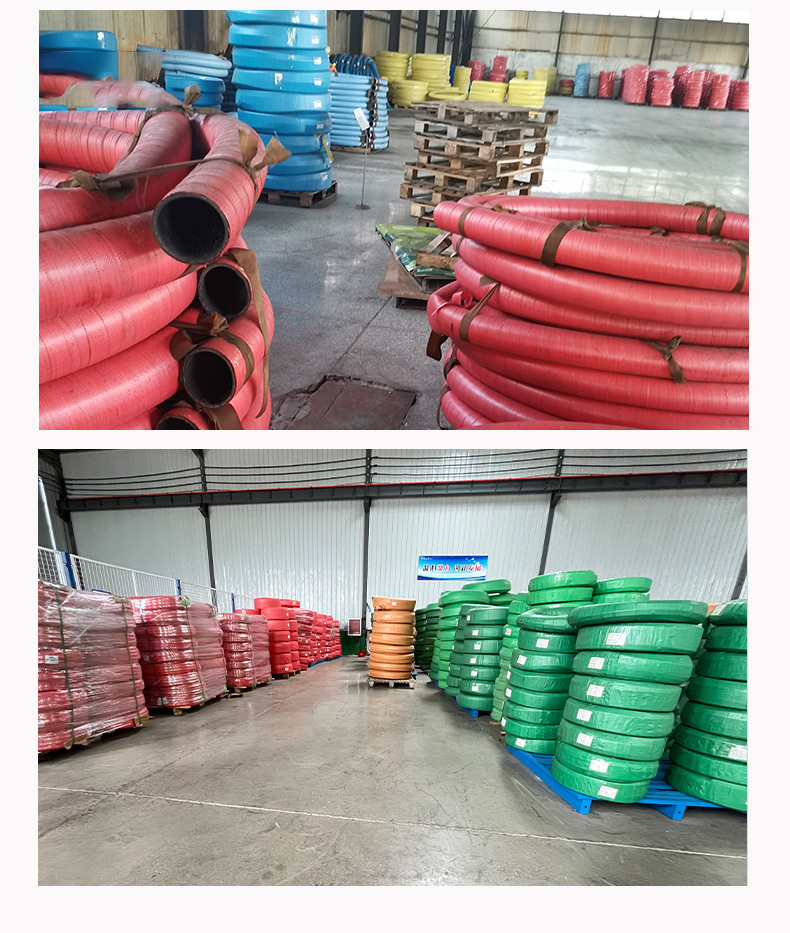

三、Packing & Delivery

二、Company Profile

Since its establishment in 2012, Jinghuan Rubber & Plastic has been deeply engaged in the research and development and manufacturing of rubber and plastic products for thirteen years. Relying on the modern enterprise management system and the layout of the entire industrial chain, it has built an intelligent manufacturing industry ecosystem integrating research and development, production, testing and sales. The company’s core product lines cover four categories: hydraulic crimping equipment, large-diameter rubber hoses, smooth low-pressure oil-resistant hoses and PVC hoses, which are widely used in engineering machinery, petrochemicals, municipal engineering and other fields. Its independently developed high-precision crimping equipment and special rubber composite material technology have broken through many technical barriers in the industry.